Application Notes for your specific use

KERAFOL ®

Areas of application KERABSORB

More...

Electronic systems increasingly require materials that both minimize electromagnetic interference and dissipate heat efficiently. With Kerabsorb, Kerafol offers a material that combines the properties of a classic gap pad with those of an EMI absorber.

The application note shows how Kerabsorb combines reliable attenuation in the high-frequency range, high thermal conductivity and defined insulation strength in a single, easy-to-integrate material.

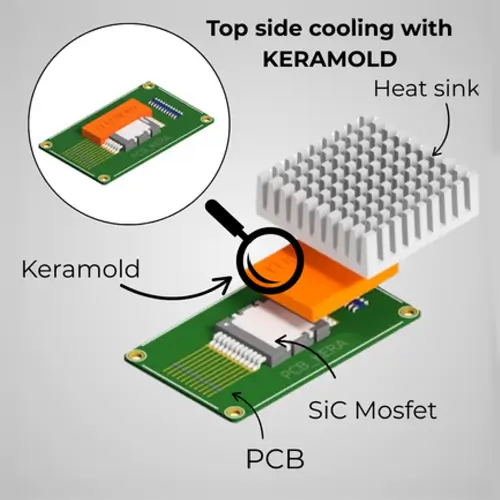

Areas of application KERAMOLD ®

More...

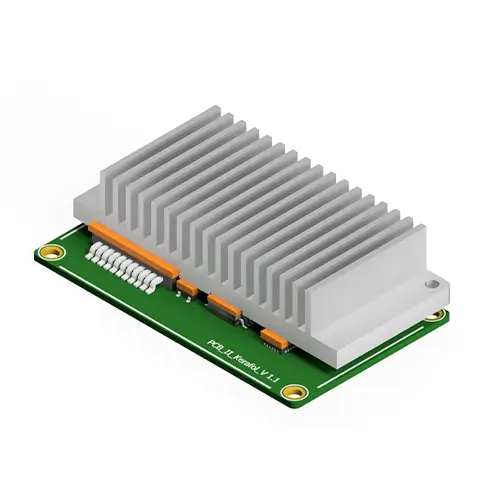

The efficient thermal connection of active components to a heat sink is one of the key challenges in power electronics. Thanks to injection-moulded 3D geometries, KERAMOLD ® enables a direct, form-fit connection between components and heat sinks without the need for additional processing steps on the metal.

The application note shows how KERAMOLD ® opens up new degrees of freedom for the design of thermal interfaces, reduces costs and minimizes thermal contact resistance at the same time.

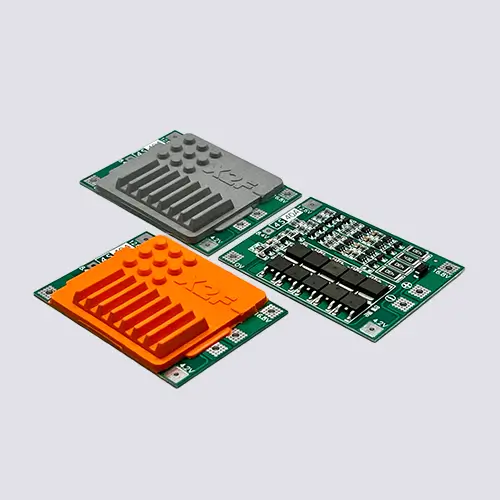

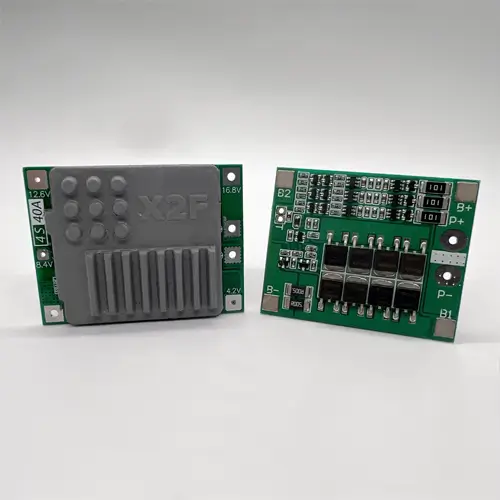

Battery Management System

More...

Our case study shows how overmolding PCBs with KERAMOLD ® 20 (W/mK) significantly reduces the component temperature while providing mechanical protection and electrical insulation – with significantly shorter process times compared to conformal coating or potting.

General overview: Silicone-free gap fillers from KERAFOL ® (GFU series)

More...

Diisocyanates are contained in many polyurethane products and have been subject to stricter REACH regulations since 2023. This affects some silicone-free gap fillers on the market, which are used in various electronic applications, especially when silicones cannot be used. The application note explains the relevant background and clarifies which silicone-free gap fillers are not affected by the regulations.

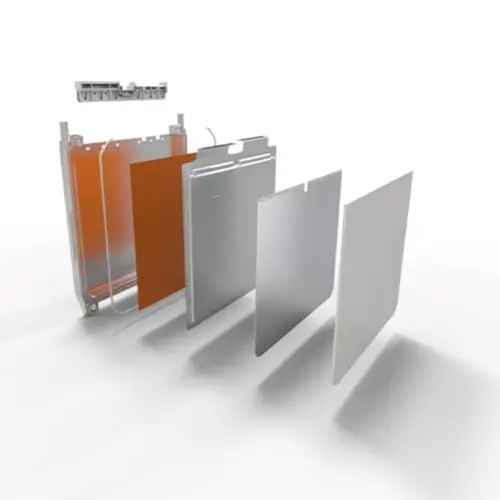

Graphite foils

More...

Especially for controlling thermal runaway scenarios. This case study shows how highly thermally conductive graphite foils from Kerafol are used in modular battery storage systems to efficiently distribute heat, reduce critical temperature peaks and slow down the transfer of energy to neighboring cells. A large-scale battery system for maritime applications is used as an example to demonstrate how graphite foils contribute to the operational safety, longevity and sustainability of modern energy storage systems.

Hybrid ceramics for high-voltage e-heaters

More...

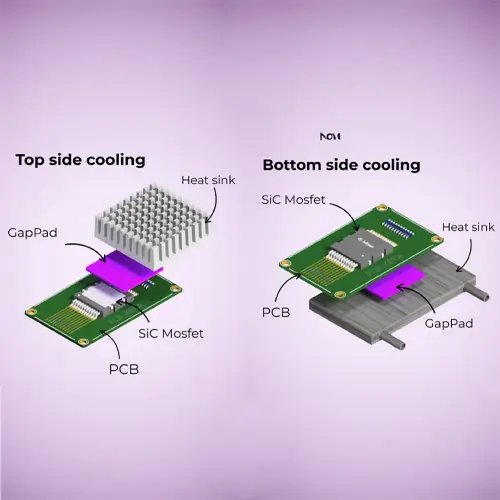

In high-performance wide band gap semiconductors such as SiC or GaN, heat is usually dissipated via the top side of the chip. The application note shows how hybrid film and hybrid ceramics as additional material options open up new design possibilities in top-side cooling – especially where thermal performance, insulation and design variants need to be flexibly combined.

A compact overview for developers who want to expand their TIM portfolio with additional solution approaches.

KERAMOLD ® – Use with electric motors

More...

Our case study compares bare windings, conventional encapsulation materials and overmolding with KERAMOLD ® 20 under realistic operating conditions on the motor test bench. result: Overmolded motors show significantly improved thermal performance and reach critical temperatures much later than encapsulated or bare designs.

KERAMOLD ®

More...

Electronics applications increasingly require solutions that combine protection and efficient heat dissipation. KERAMOLD ® offers a new approach to this: a thermally conductive injection-moulded granulate that combines functional integration and thermal management.

The application note shows how KERAMOLD ® can be used to open up new design possibilities for modern electronic modules – from component design to system integration.

Overview:

Thermal management for SiC semiconductors

More...

With high-performance wide band gap semiconductors such as SiC or GaN, heat is usually dissipated via the top of the chip. The application note shows how KERAMOLD ® in combination with the overmolding process can protect and cool active components precisely.

With KERAMOLD ®, thermal conduction, electrical insulation and mechanical stability can be combined in a single process step – thus opening up new degrees of freedom for the design of high-performance top side cooling solutions.

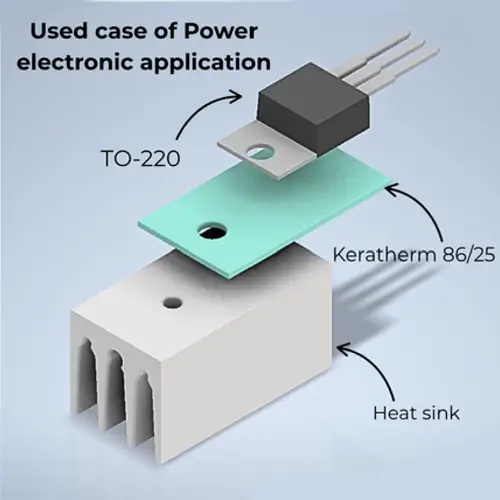

Specific heat conducting foil blanks for TO component

More...

TO packages such as TO-220 or TO-247 are widely used in power electronics. The application note shows how KERATHERM films optimally combine thermal conductivity and electrical insulation to enable efficient cooling and easy assembly directly on the standard packages.

Developed for different power classes, the films offer a flexible, automatable solution for modern power electronics.

Thermal management for SiC semiconductors in the 800V range

More...

In high-performance wide band gap semiconductors such as SiC or GaN, heat is usually dissipated via the top side of the chip. The application note shows how hybrid film and hybrid ceramics as additional material options open up new design possibilities in top-side cooling – especially where thermal performance, insulation and design variants need to be flexibly combined.

A compact overview for developers who want to expand their TIM portfolio with additional solution approaches.