Consumer Market

Industry / Markets

The electrical engineering and electronics industry is one of the largest branches of industry in Germany.

With its cross-sectional technologies, it is a driver of innovation and technical – and therefore also social – progress.

The industry is characterized by excellent competitiveness and a high level of systems expertise.

This is also demonstrated, for example, by the consumer electronics, electrical household appliances and power tools sectors, the latter of which can look back on a long history in Germany and continue to be a growth driver.

Both are regarded as “solution industries”, contribute significantly to Germany’s future viability and influence people’s lives and coexistence.

The market is very price-driven, which means that highly automated production technologies are required in order to remain competitive.

Although some components still come from Asia, mainly for price reasons, there are also more and more local alternatives.

The renewed focus on quality and the ability to offer long-lasting and quality-stable appliances is once again coming to the fore due to the concept of sustainability.

Household electrical appliances

Household appliances include, for example, “white goods”, room air conditioners and small electrical appliances (e.g. coffee machines).

The white goods sector in particular covers a wide range of appliances, including washing machines, refrigerators, ovens and dishwashers.

In addition to the mechanics, the design of the controls plays a major role, and many semiconductors are now being used here too.

Especially under full load or under stress due to rapid temperature cycles, these are subjected to high stress.

The corresponding switching processes of the semiconductors (e.g. IGBTs) generate a high level of heat.

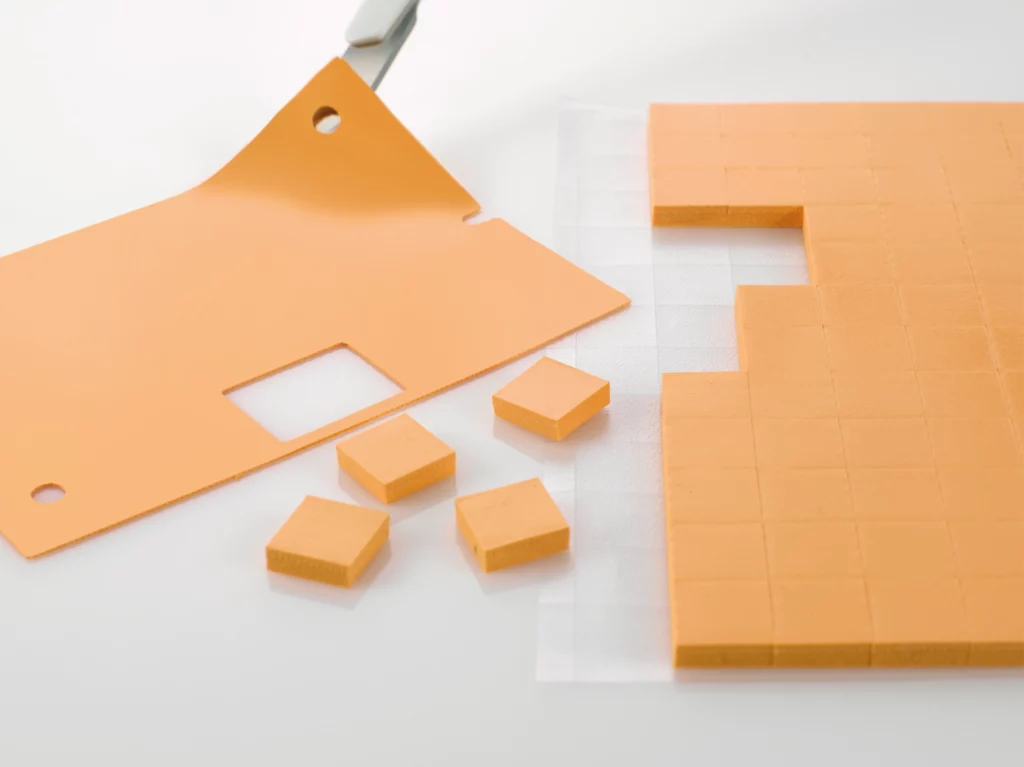

As electronic assemblies are usually becoming smaller, but the corresponding performance requirements are increasing, the thermal management of the electronic assembly is an essential component for a functional design.

Solutions

for electrical household appliances

Power Tools

Power tools are a traditionally strong market in Germany.

A power tool is any tool that is used by means of an electric drive and thus significantly simplifies the work to be performed.

The most important power tools include electric drills and grinders as well as jigsaws and circular saws, but screwdrivers such as cordless screwdrivers are also manufactured with electric drives.

Power tools are available in corded and cordless versions.

An accumulator is used as a power source without a direct connection to the power grid.

In this way, cordless tools increase mobility when carrying out work.

For a higher degree of compatibility, certain standards have been established in the field of rechargeable batteries (e.g. 18V connections and performance).

A rechargeable battery can therefore not only be used for different devices within the product range of one supplier, it can also be used in some cases with a device from another manufacturer.

There are major differences in the performance and often also the general quality of power tools, but this also depends on the intended use.

Power tools for private DIY enthusiasts should often be inexpensive, while professional power tools should be powerful.

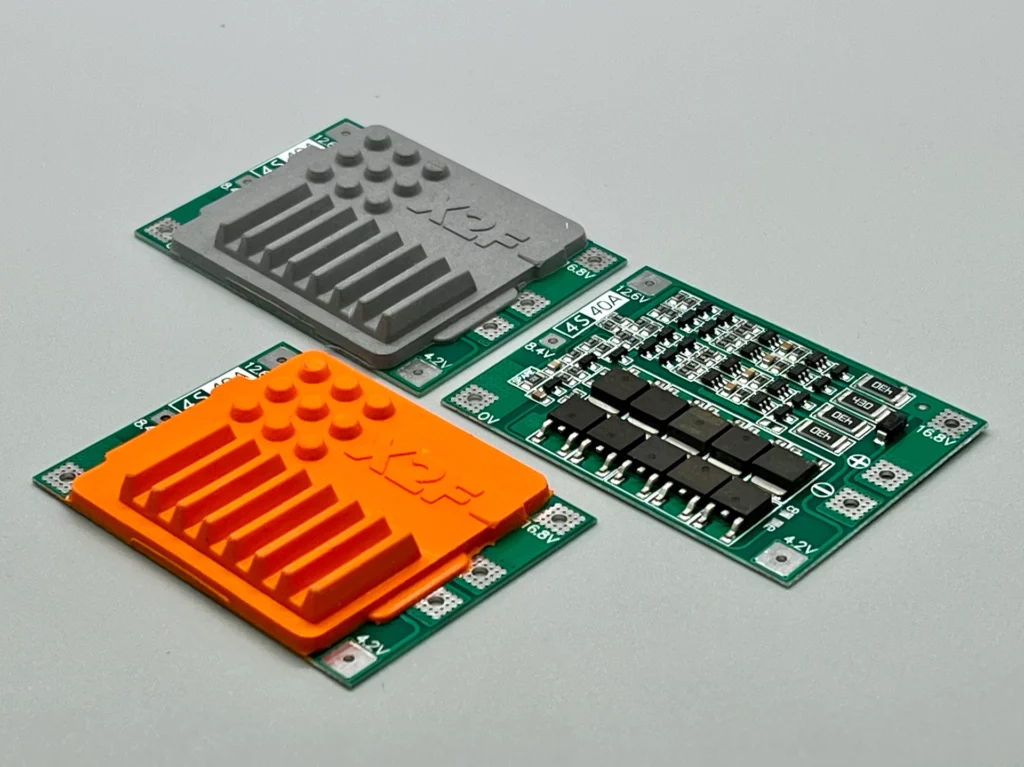

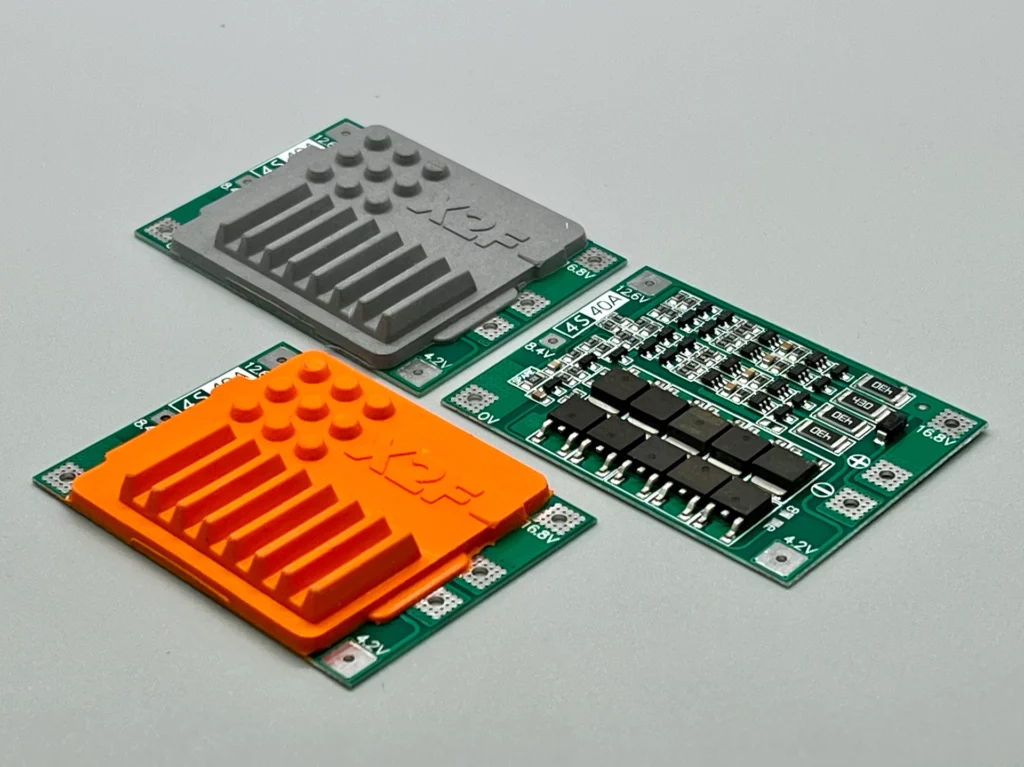

The power density in electronic devices for power tools is constantly increasing.

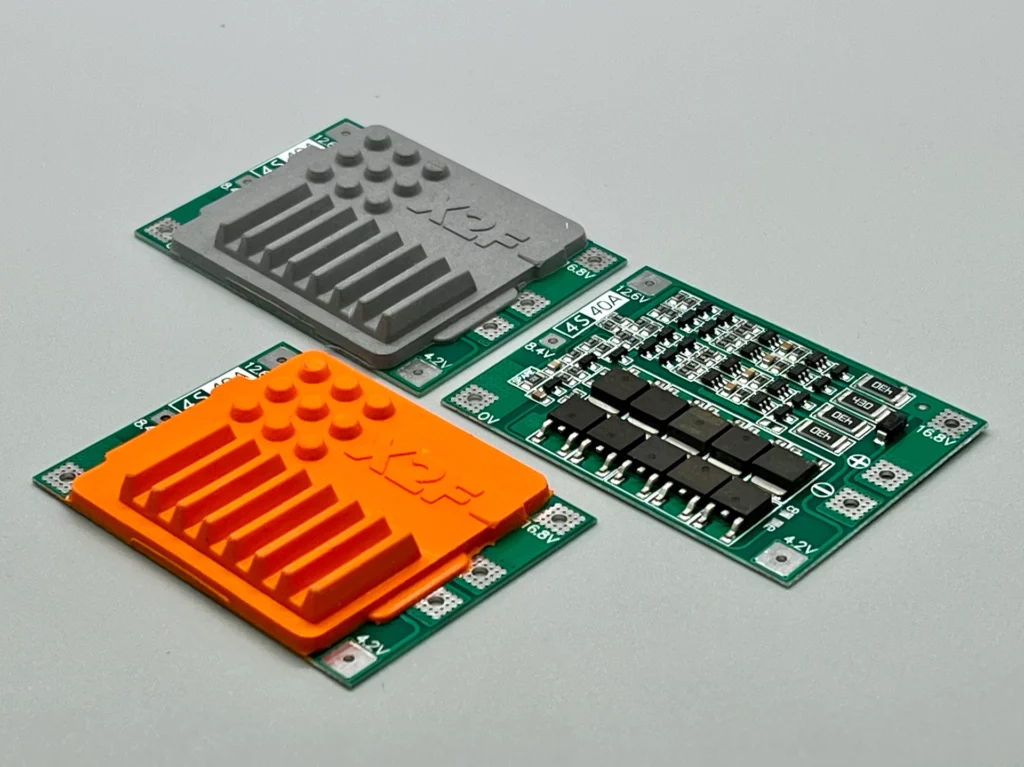

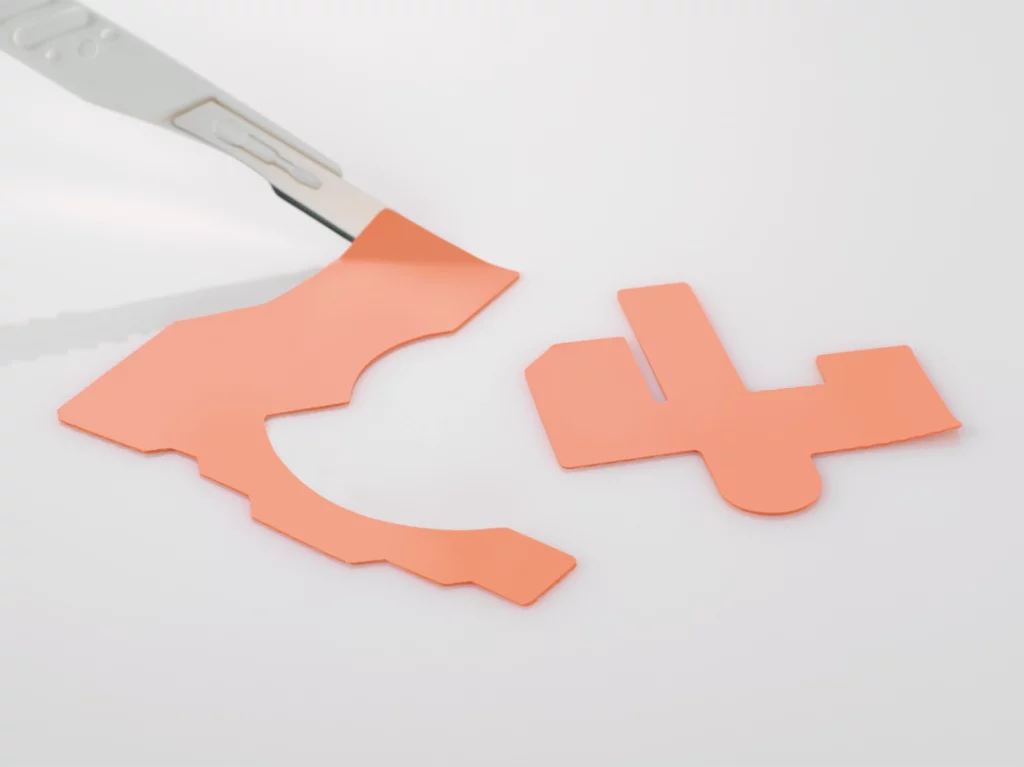

This high heat level, which is generated by battery cells and electronic components (e.g. semiconductors), requires intelligent heat transfer from the electronics to the heat sink (e.g. cooling plate or aluminum housing).

In addition to the thermal parameters, the voltage level is also continuously increasing in many applications, which means that reliable electrical insulation between the electronics and the housing is crucial.

Solutions

for Power Tools

Robot mower

In terms of their function and design, robotic lawn mowers can be categorized both as electrical household appliances and as power tools.

For some years now, robotic lawn mowers have been used more and more frequently, with a strong upward trend, making lawn care much easier and improving the lawn itself through daily mowing.

The heart of the robot mower is the control unit and the battery, the interaction between the two components is crucial for the end result.

Due to the daily use of the robot in changing environmental conditions, sometimes with high humidity, the sensitive electronic components are subject to high demands.

The battery must therefore be temperature-resistant and maintain a constant performance and therefore a comparable range even after several load cycles. Suitable thermal interface materials (TIMs) can be used to connect battery cells and the entire battery module, including the battery management system (BMS), to a heat sink. This allows heat to be transferred from the battery cell to the environment and prevents it from overheating. Electronic components in the form of semiconductors, for example, which are installed on circuit boards, generate a high level of heat.

Solutions

for robotic lawnmowers

eDrone

The market of remotely controlled flying units is growing rapidly.

It`s now not only for fun, the role of drones have become more serious among last years.

Starting from video and pictures shooting, through support for media market or geodesy and cartography, ending on military usage, these machines are taking leading position in supporting professionals.

The development of energy storage systems and miniaturization of electronics made drones lighter and let them work longer on single power load.

Modern drones are equipped with complex battery packs which are not only allowing it to fly long distances or long hours.

Variety of instruments, such as cameras, sensors or antennas, need a lot of power to work.

These factors increase the demand for energy, parallel the charging of the battery should be done quickly.

For those reasons correct thermal management plays an important role.

The reliability of electronics and other components can be kept on a high level if the temperature is controlled.

Good surface connection of heat source and heat sink can only be achieved if thermal interface materials (TIMs) are used.

Next to the heat management, the protection of electronics itself is very important.

A Hazardous environment, in which drones are operating, implies variety of circumstances which can lead to the damage of sensitive components.

TIMs are perfect in vibration control, electrical insulation, protection against dust and humidity or even sound proofing.

Solutions

for eDrones

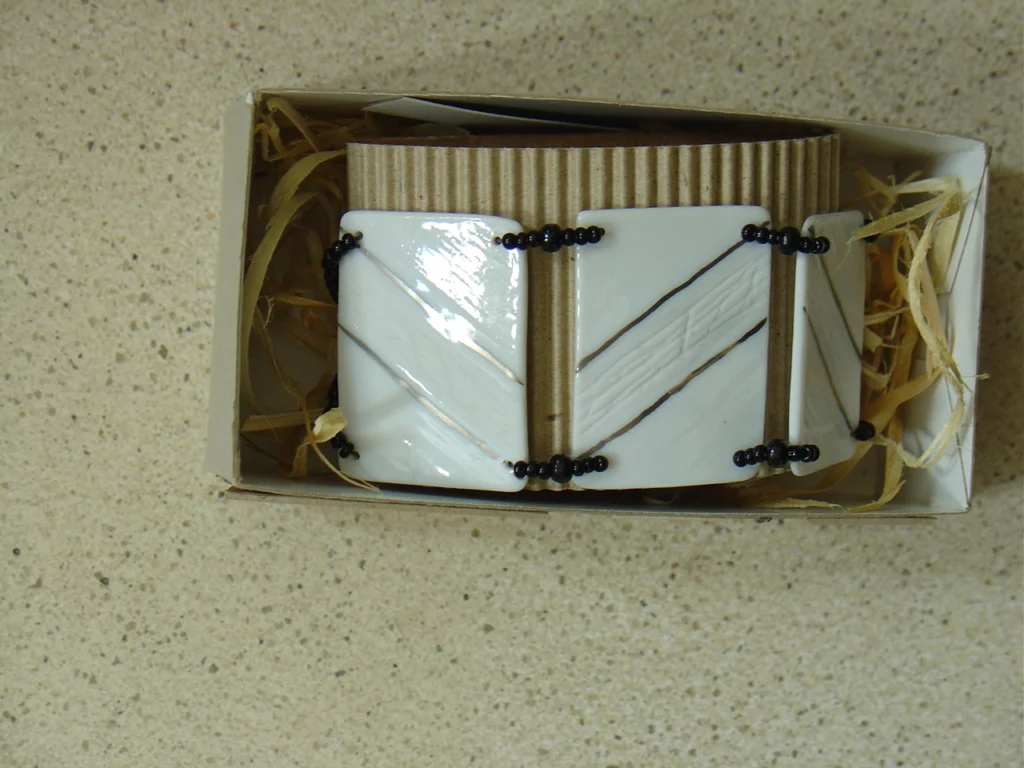

Luxury Goods

Thin and fine ceramic layers with a material thickness of 40 µm to 0.5 mm made of zirconium oxide or aluminum oxide are an ideal partner for optical, haptic and mechanical requirements due to their material properties such as high hardness, toughness and resistance to temperature and electrical flow.

Finely finished ceramic surfaces always offer an elegant appearance of high quality.

Be it in the jewelry industry, horology or simply to enhance the surfaces of humidors, jewelry boxes or similar. The ceramic ensures an almost imperishable appearance with a noble, cool haptics and enhances every surface, regardless of whether the object is made of wood or metal. Even elaborate plastics can be given the finishing touch. We can recommend our Keralpor sintered plate to watch manufacturers who already produce their own ceramics to support their production. Take a look at the sintering technology section.