Kiln furniture

by KERAFOL®

Various aluminum oxide kiln furniture is available for the sintering of high-performance products.

We offer our customers Keralpor Z especially for the production of high-temperature fuel cells.

The kiln furniture is coated to prevent the formation of NiAl2O4 spinel as a result of the reaction between Al2O3 and NiO, thereby maintaining the catalytic activity of the anode side.

You can find more information about our kiln furniture in the section Ceramic Tapes & Substrates.

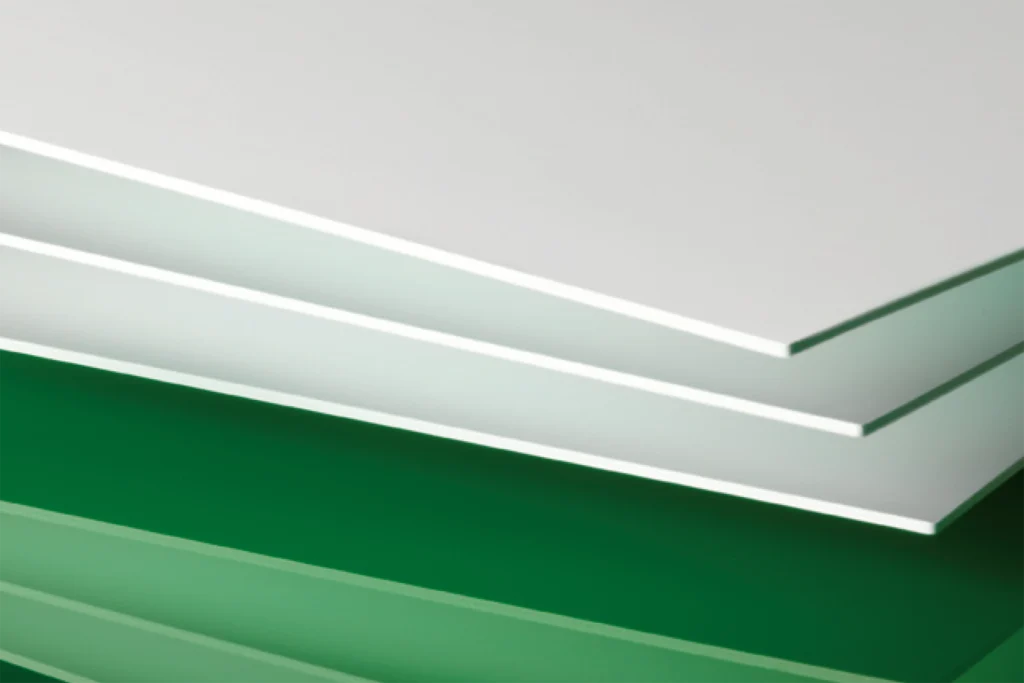

Dimensions

In addition to kiln furniture in the standard formats of 148 x 210 mm²; 100 x 100 mm²; 150 x 150 mm² and 168 x 168 mm², we offer a variety of round and rectangular geometries depending on customer requirements.

All formats are available in thicknesses of 1.0 / 1.5 / 2.0 mm.

Advantages

of kiln furniture

- Cost-effective setters for high-quality ceramic and metal injection-molded parts (MIM components)

- Gases can diffuse freely through the carrier and the coating

- Customizable dimensions of the setter are possible

- Good mechanical strength compared to high open porosity

- Very good flatness and surface quality