Defense & Aerospace

Applications

In its White Paper European Defense-Readiness 2030, the European Commission urgently pointed out Europe’s inadequate defense readiness. Decades of underinvestment have left the continent poorly prepared for threats, particularly from Russia. A strong and innovative defense industry sector is seen as a prerequisite for peace and security.

An important part of this is the use of new and innovative technology, which is why electronics is one of the core elements that many European companies are currently working on. The function and longevity of the electronics depends on the appropriately designed “thermal management”, especially fast temperature cycles and demanding environmental and operating conditions represent a mechanical and thermal load for electronic assemblies. Kerafol has been actively involved in the development of new products and solutions for this key market for many years. As a result, various Kerafol materials are already an integral part of e.g. drones, current transformers or control units

Areas of application

Defense & Aerospace

Military & Aerospace

Solutions

for Military & Aerospace

Drones

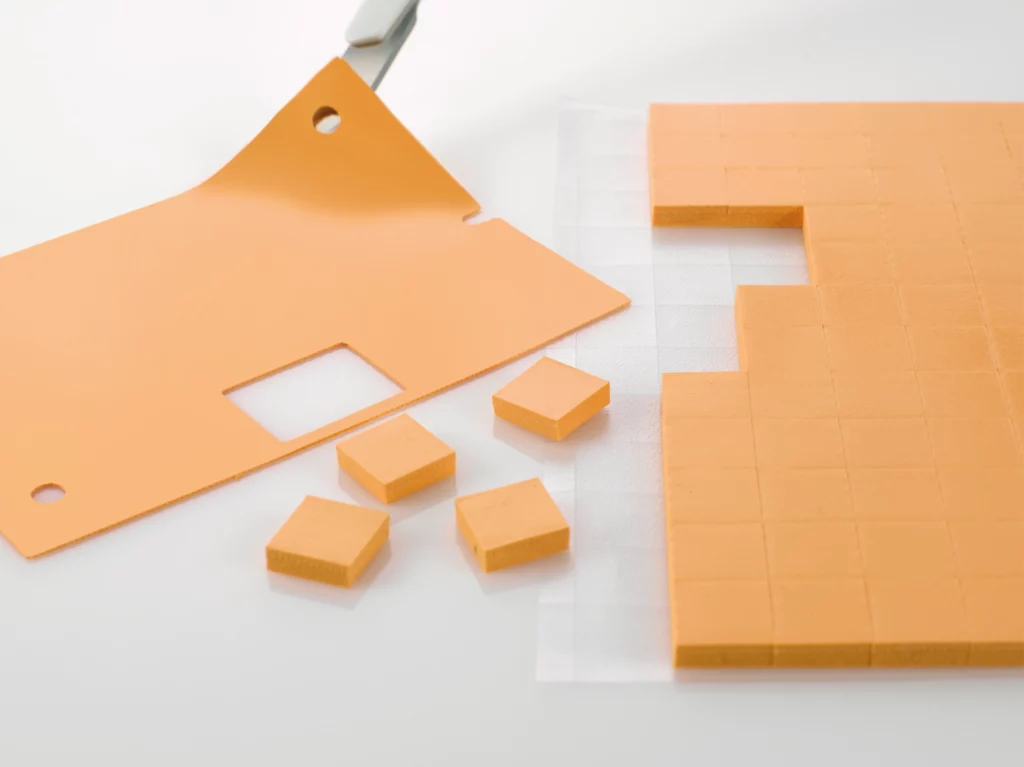

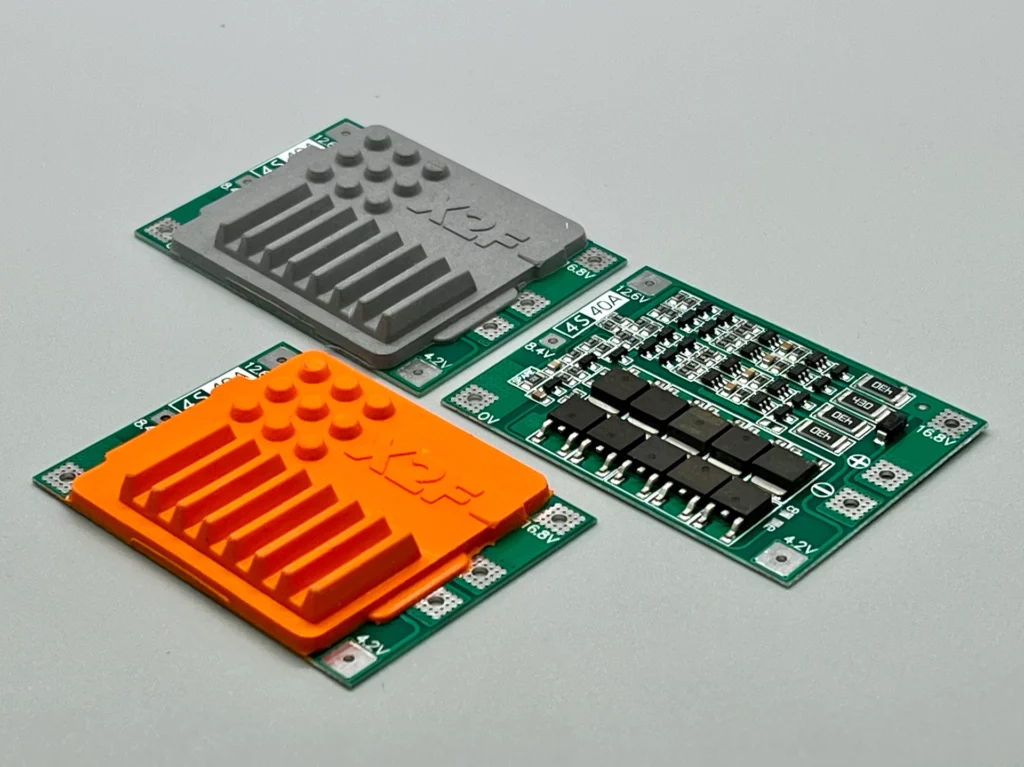

Modern drones are equipped with complex battery packs which are not only allowing it to fly long distances or long hours. Variety of instruments, such as cameras, sensors or antennas, need a lot of power to work. These factors increase the demand for energy, parallel the charging of the battery should be done quickly. For those reasons correct thermal management plays an important role. The reliability of electronics and other components can be kept on a high level if the temperature is controlled. Good surface connection of heat source and heat sink can only be achieved if thermal interface materials (TIMs) are used. Next to the heat management, the protection of electronics itself is very important. A Hazardous environment, in which drones are operating, implies variety of circumstances which can lead to the damage of sensitive components. TIMs are perfect in vibration control, electrical insulation, protection against dust and humidity or even sound proofing.

Solutions

for drones

Current transformers and current storage

To ensure that Europe remains independent and resilient, a reliable European supply base is crucial. Cooperation with proven European suppliers – who guarantee quality, reliability and long-term availability – should prevent supply bottlenecks and ensure technological sovereignty.

A key example of the necessary industrial basis are power conversion components (e.g. DC/DC and AC/DC converters). Although often inconspicuous, they are indispensable for the operation of modern military systems such as drones, vehicles or ships. They must meet strict military standards (MIL-STD/MIL-SPEC) in order to function reliably under extreme conditions. Power storage systems in various forms are also increasingly in demand; here, too, the focus is on efficiency and reliability under demanding environmental and operating conditions.

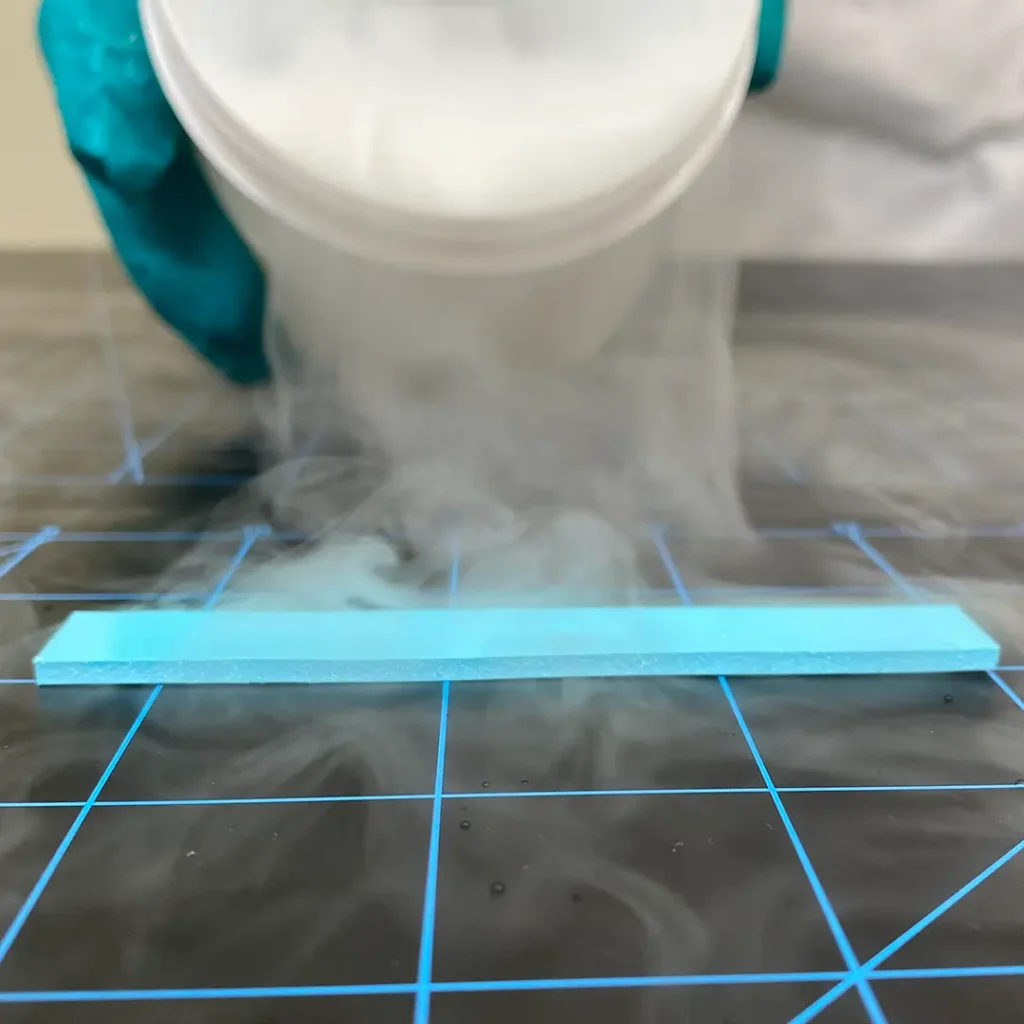

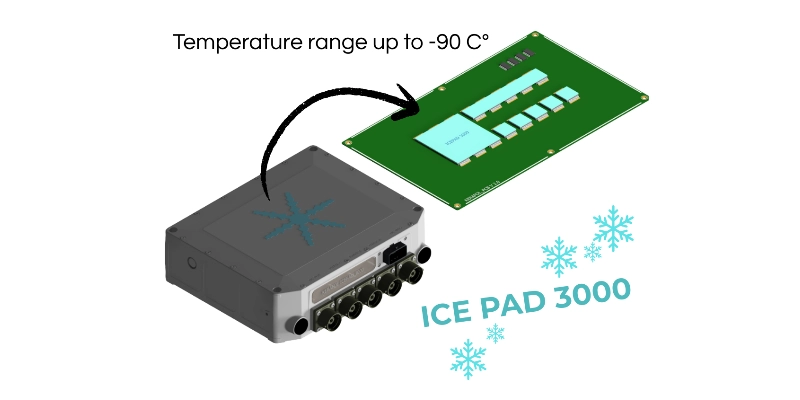

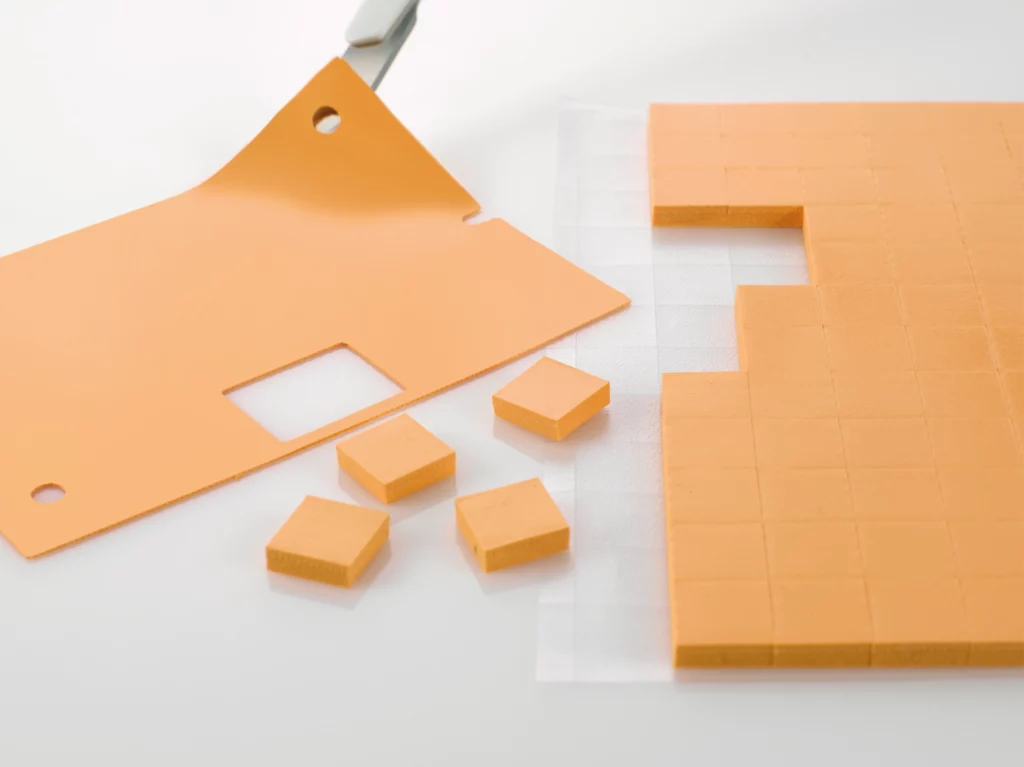

The first product in the new series is the ICE PAD 3000, with an extreme temperature resistance of -90 °C to 200 °C. Conventional materials are only approved up to a maximum of 60 °C and at the -60 °C required by MIL-STD/MIL-SPEC, their softness and elasticity can decrease significantly, which can then lead to a drop in the performance of the electronics. The ICE PAD 3000 retains its basic properties even at -60 °C and is therefore an extremely reliable component for extreme requirements. Further products with this temperature resistance will follow.

KERAFOL® is familiar with the associated application technology and also offers pilot plant trials with dosing systems.